present

02.2025 - now

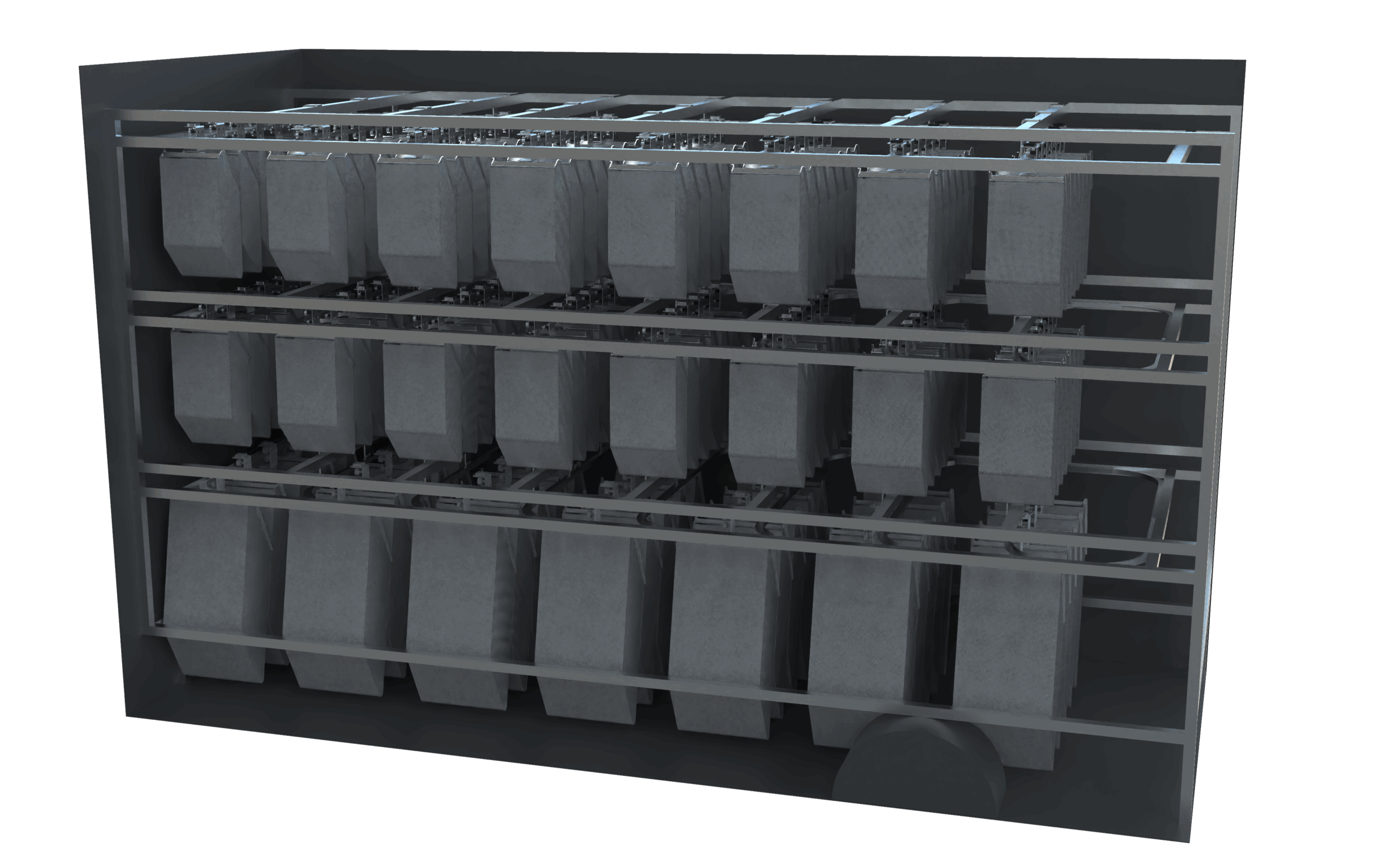

The development throughout my Master built the foundation for my Final Master Project. In this project, I developed an automated load, sort, and unload system for packages in last-mile package delivery vehicles. I incorporated and expanded on the development themes detailed below.

Image 6: Video story to highlight the conceptual solution of an in-vehicle pouch sorter

Image 7: Video story that was used to present the problem and pouch sorter concept to PostNL

Storytelling & Contextualizing

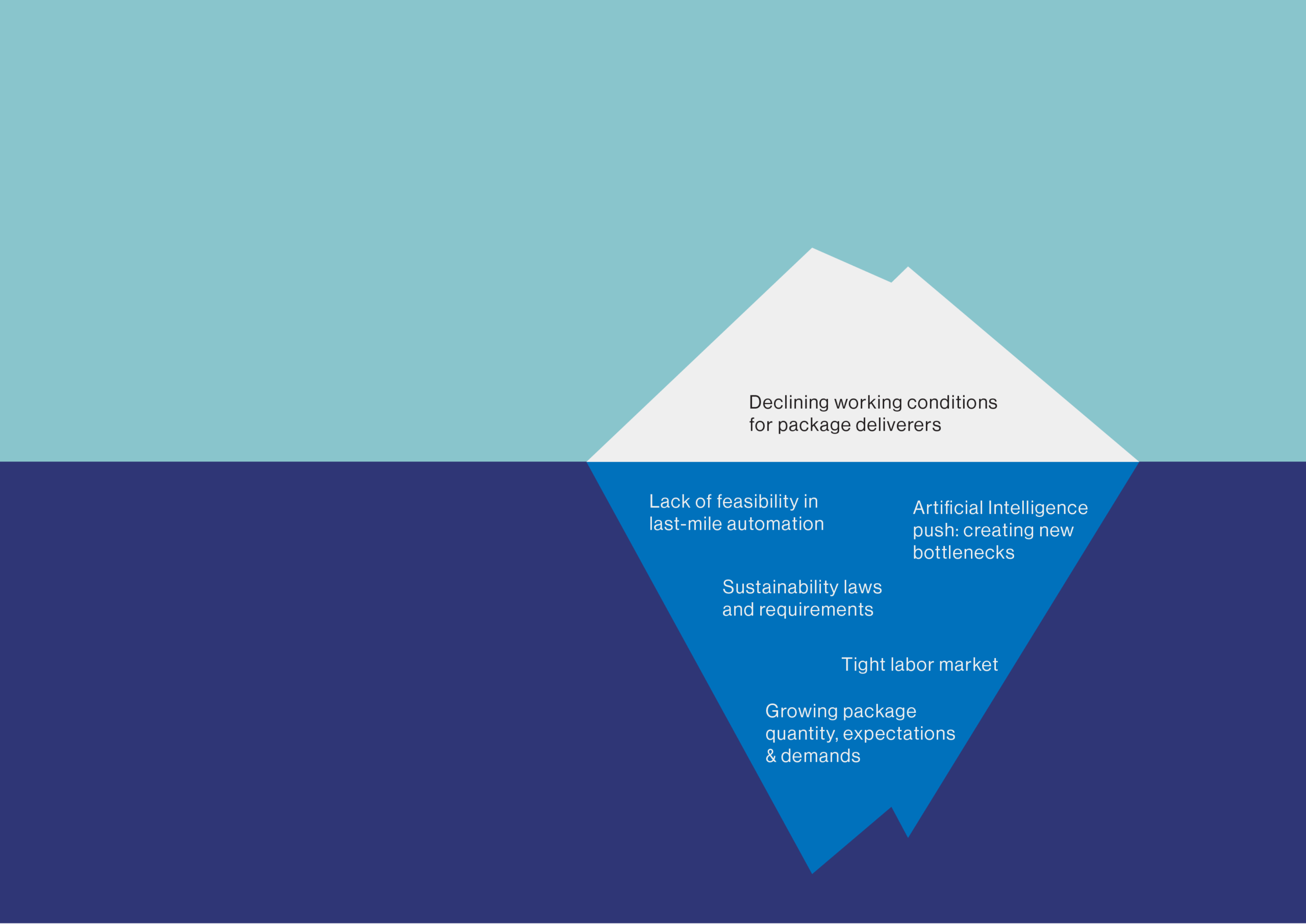

My goals related to this theme were to define and quantify a problem from the angles of all core problem owners and translate these to emotional and analytical stories, addressing different audiences. Therefore, I emphasized understanding the problem context of excessive manual package handling from a first, second, and third-person bottom-up (in-context) and top-down (analytical, historical) perspective. I talked to package deliverers, conducted market and technology benchmarks, and thematically analyzed annual reports, job and customer reviews, and trend radars, accounting for the perspectives of deliverers, customers, and PostNL. These insights were aggregated and translated into still and videographic stories for user empathy, user insight, problem validation, and design evaluation (Images 1 to 7). Through this, I got better at recognizing and connecting trends and seeing causalities in problems, enabling more appropriate design decisions to address them. This improved my confidence in conceptualizing, evaluating, and discussing my design. Videographic storytelling emerged as an efficient and effective tool for stakeholder involvement and evaluation, so I want to make this a more inherent part of my future design processes.

user & society | design & research processes

business & entrepreneurship | creativity & aesthetics

Image 12: Loading a package into the pouch sorter

Image 13: Unloading a package from the pouch sorter

Interaction Design

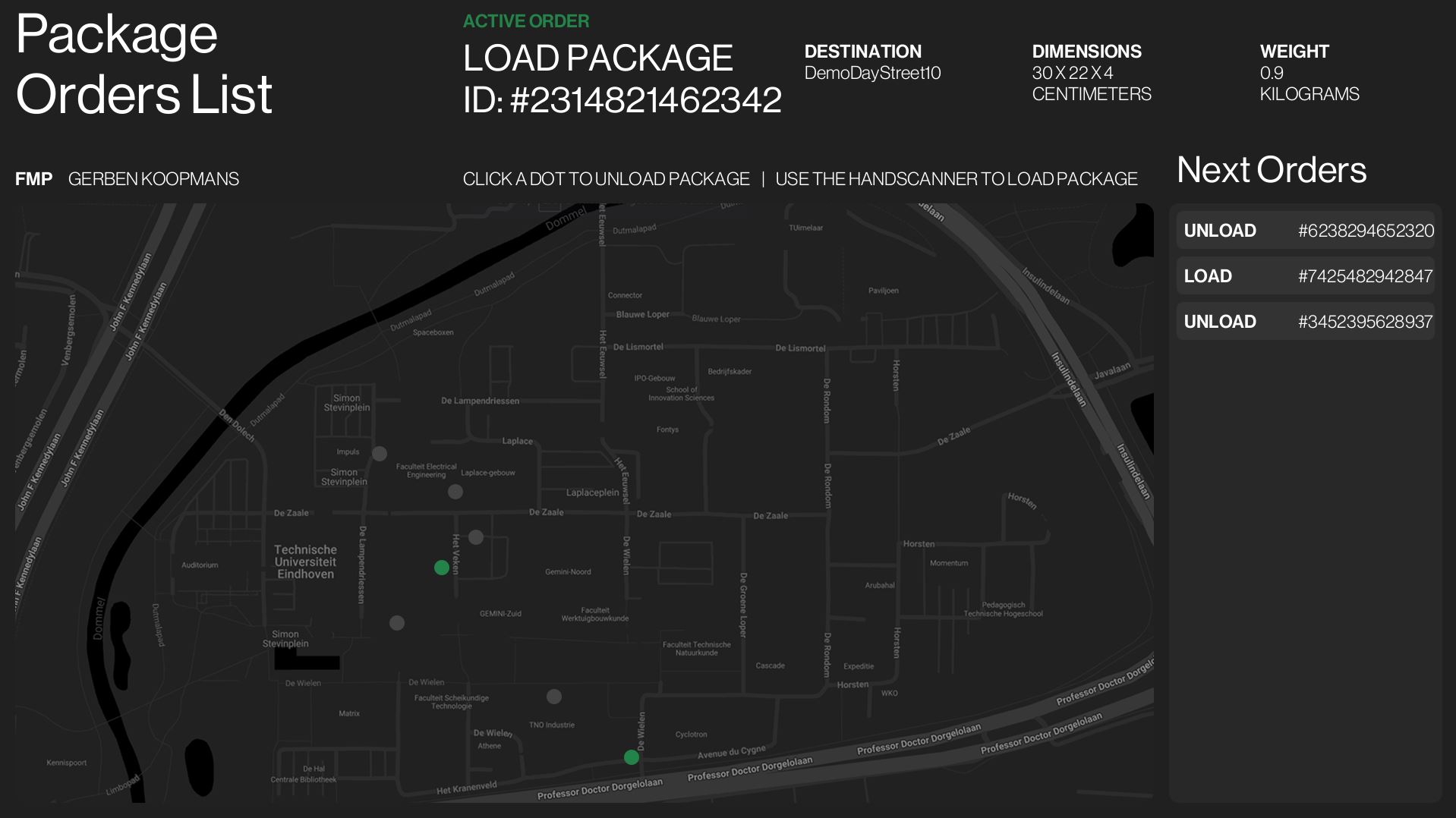

The central goal for my Final Master Project was to install an interactive prototype of a package sorting system in a delivery vehicle. This included enabling independent interaction with the prototype, for which I developed an online (un)load dashboard to use the prototype with a hand scanner (Images 8 to 10). Moreover, the problem context required ergonomic interactions (Images 11 to 13), which provided a new dimension to my understanding of interaction design that affected my design vision. The sole action of designing interactions can be used to improve wellbeing, an especially relevant scope in the context of (intra-)logistics, which experiences a major trend in improving ergonomics for industry workers. Hence, it will be one of the main ways to realize my design vision as Project Manager at EPHI. Another new perspective on interaction design that I learned is in assembly interactions. Moving into a more industrial context meant that the manufacturability of my designs became a bigger consideration, requiring intuitive, efficient, and aesthetic assembly by employees. Key considerations I learned are to design with minimal variations of bolts and nuts to avoid confusion, same material thicknesses to enable easier processing, slotted holes for adjustment, and distinct assembly steps for batching (Image 14). These will play a more crucial role in my future design concepts.

technology & Realization | creativity & aesthetics

user & society

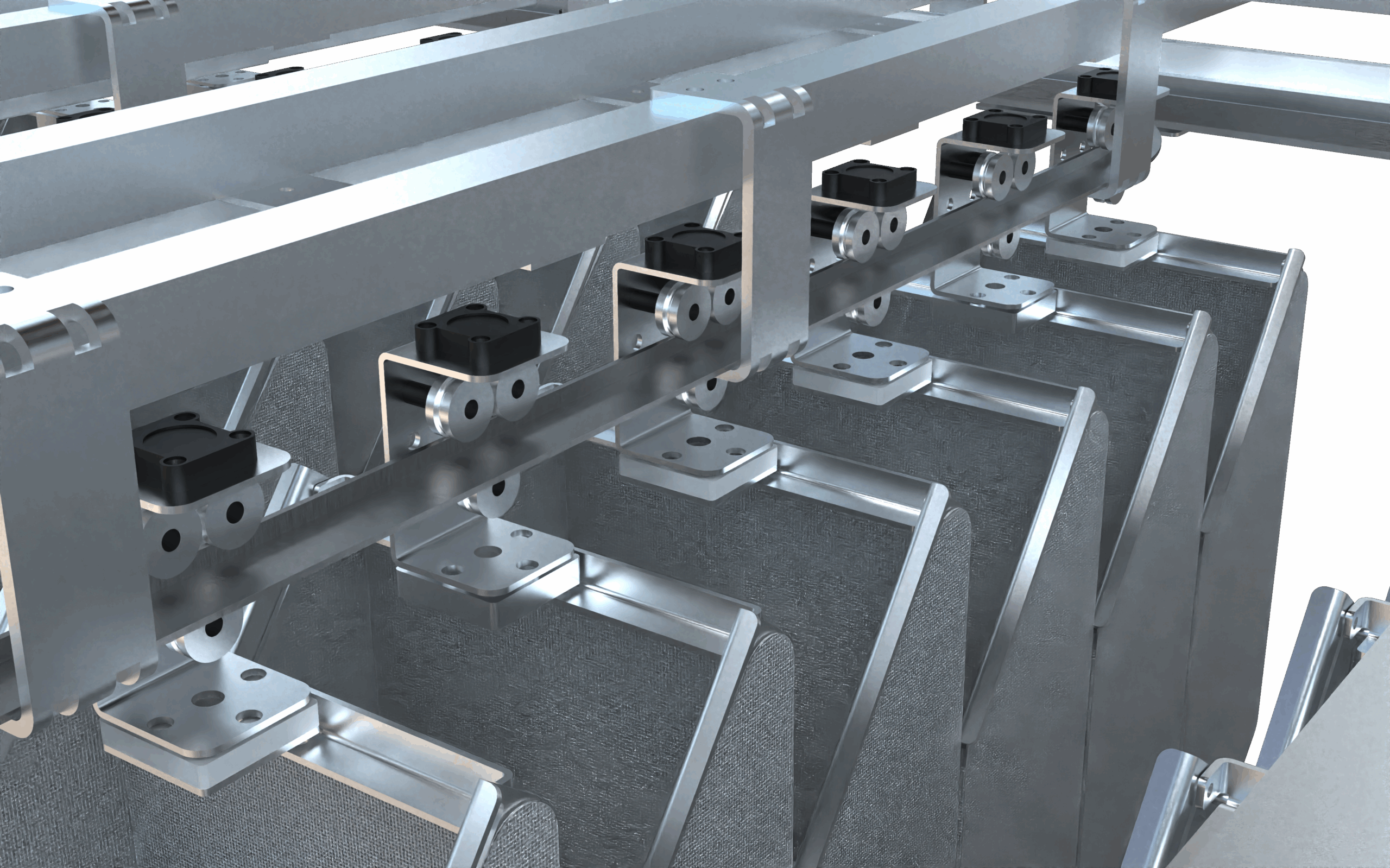

Image 15: True to life assembly of pouch sorter

Modeling & Engineering

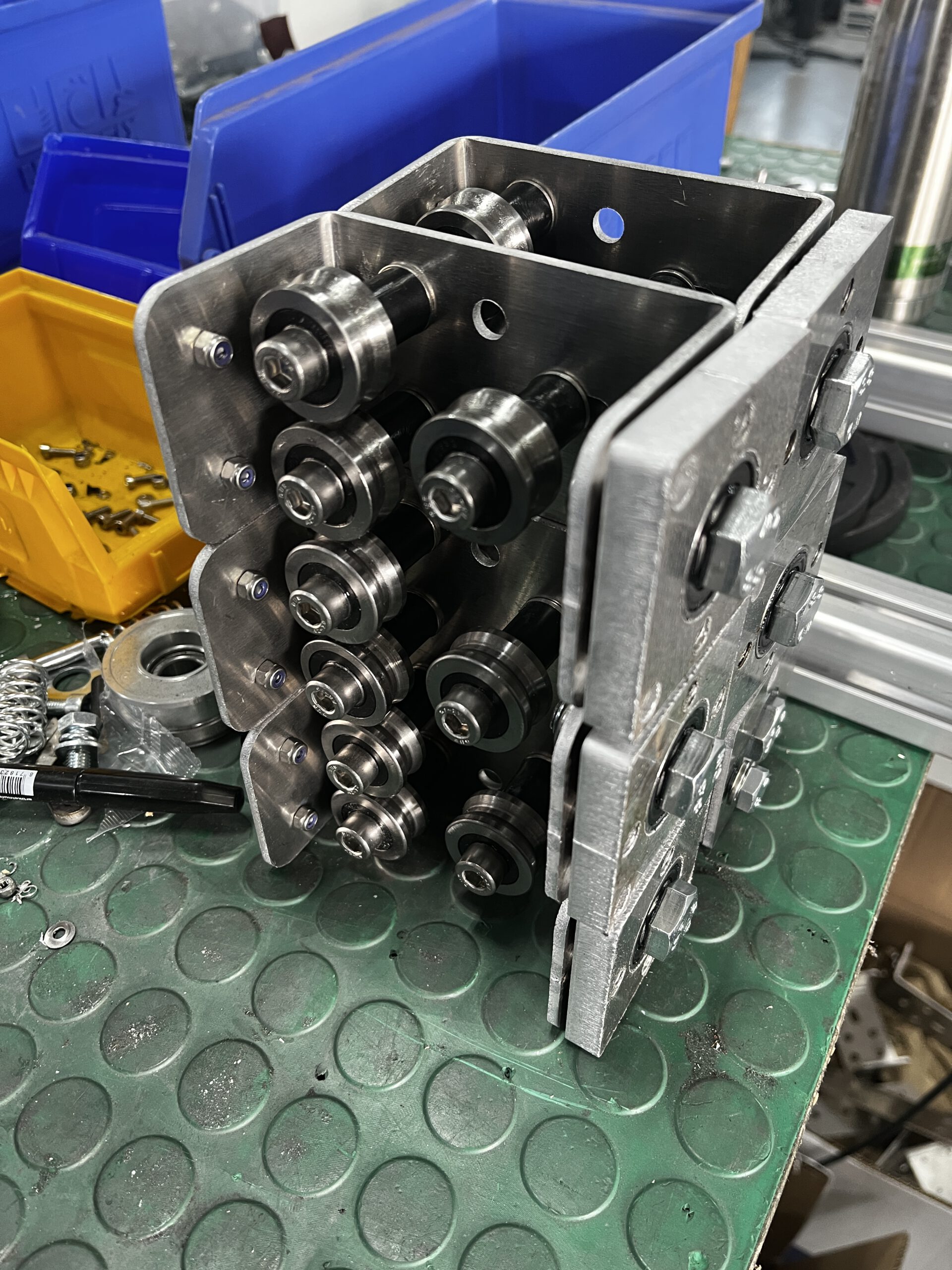

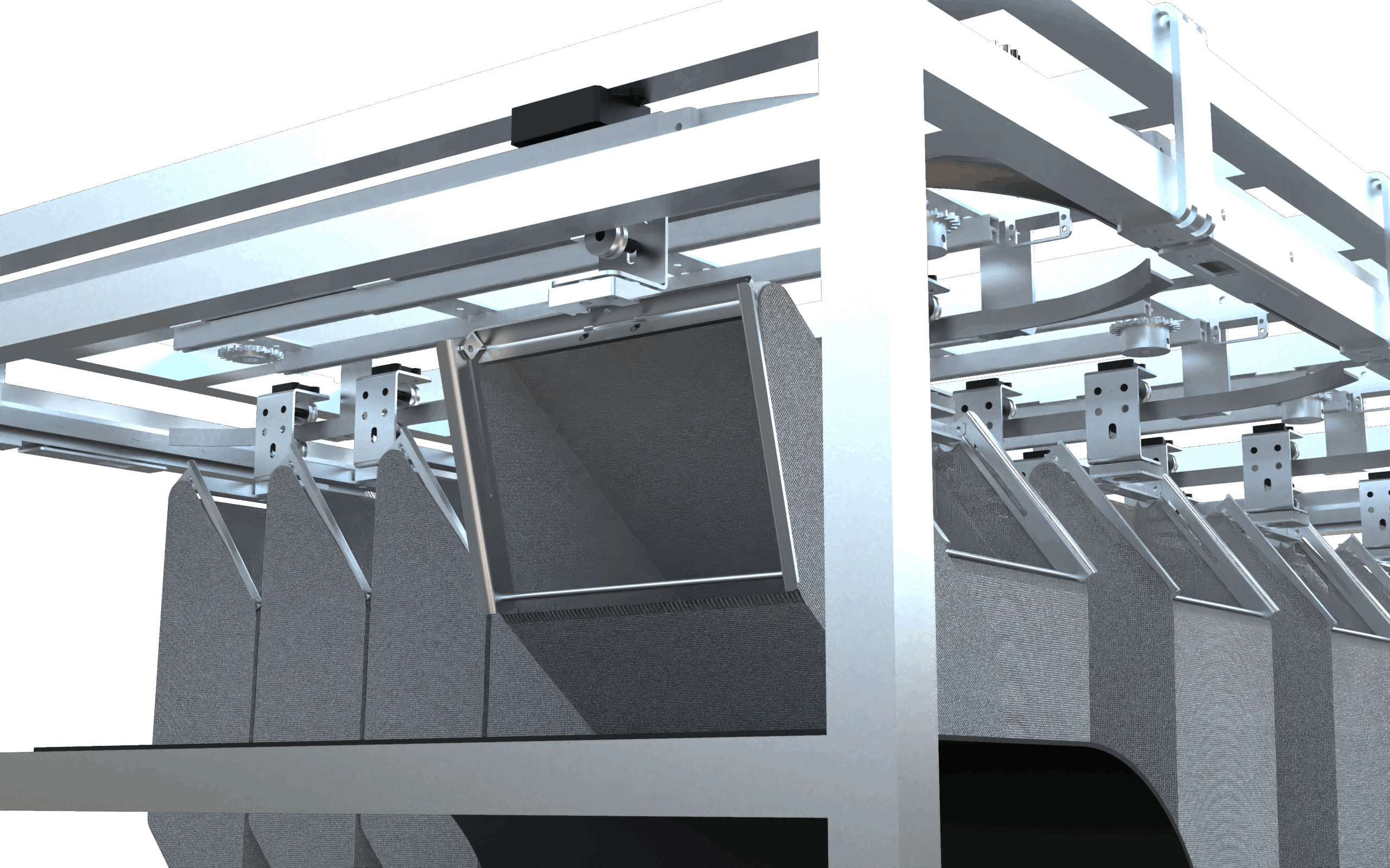

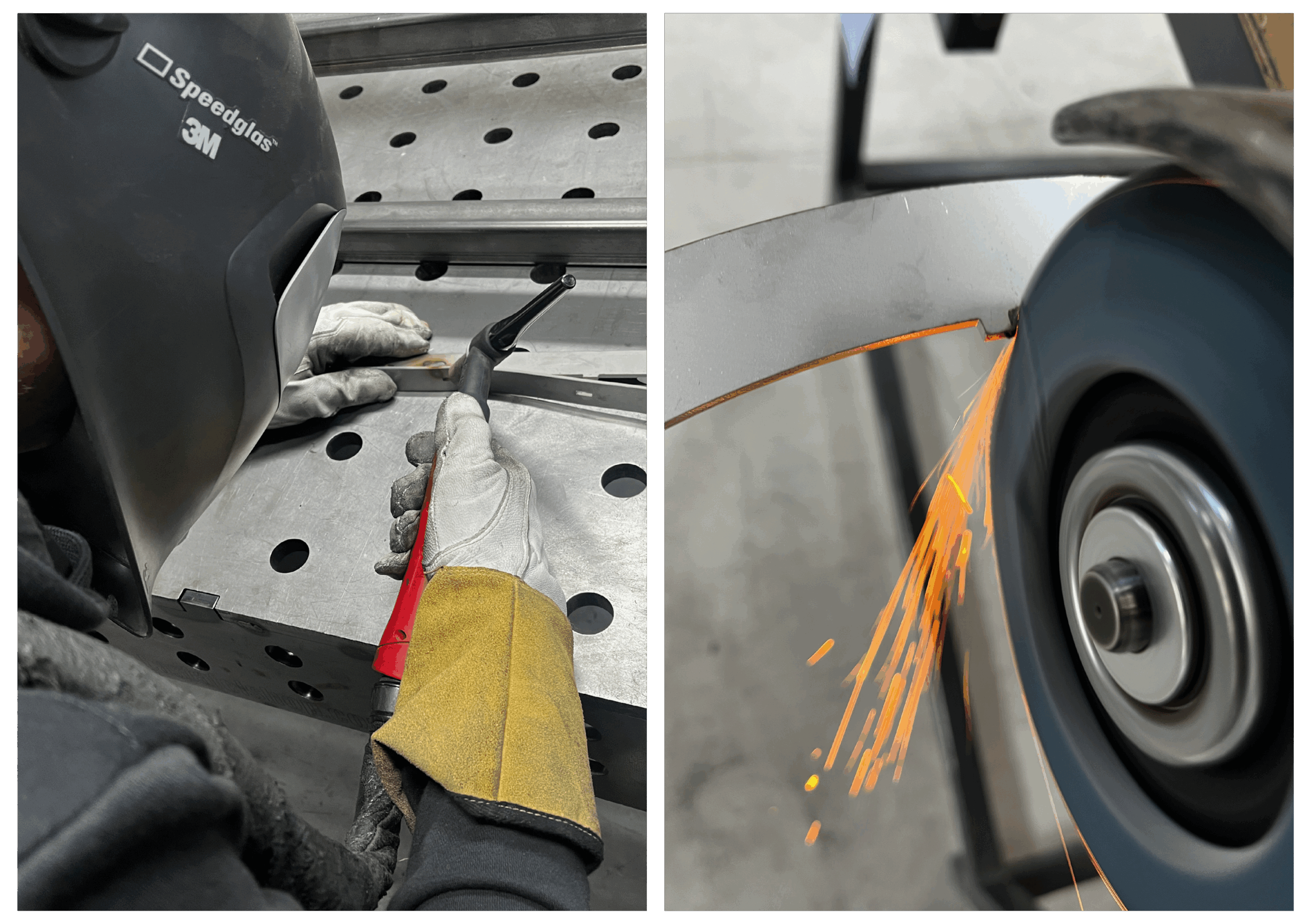

This theme was central to my Final Master Project, even more so after the pivot in my planning toward individually modeling and engineering the prototype. My goals were to learn how to make true-to-life 3D assemblies for iteration, evaluation, and collaboration, and to render them in Keyshot for external communication, which I both satisfied (Images 15 to 18). With many metal components and extensive delivery times, I needed to model creatively to enable quick iteration. Therefore, almost all components were first iterated and explored through 3D printing (Image 19) and designed to be flexible through slotted and extra holes to anticipate future iterations (Image 20). 3D rendering and this new approach to 3D modeling connected Technology & Realization to Creativity & Aesthetics, and made modeling a thoroughly integrated part of my design process. In engineering the prototype, I pushed the boundaries of my expertise by developing different subsystems reliant on great precision. This reinforced the importance of adjustability, since real-life forces affect everything differently than can be anticipated in an online model (Images 21 to 23). This process taught me practical engineering skills, like choosing and processing different materials (Image 24), relevant for conceptualizing technical solutions as Project Manager. However, it also reinforced that I want my role to be more on the prototyping side than hard engineering.

technology & Realization | creativity & aesthetics

Image 25: Scanning pouches with RFID

Image 26: Servomotor rail switch using flexible plastic

Image 27: Servomotor pouch endstop

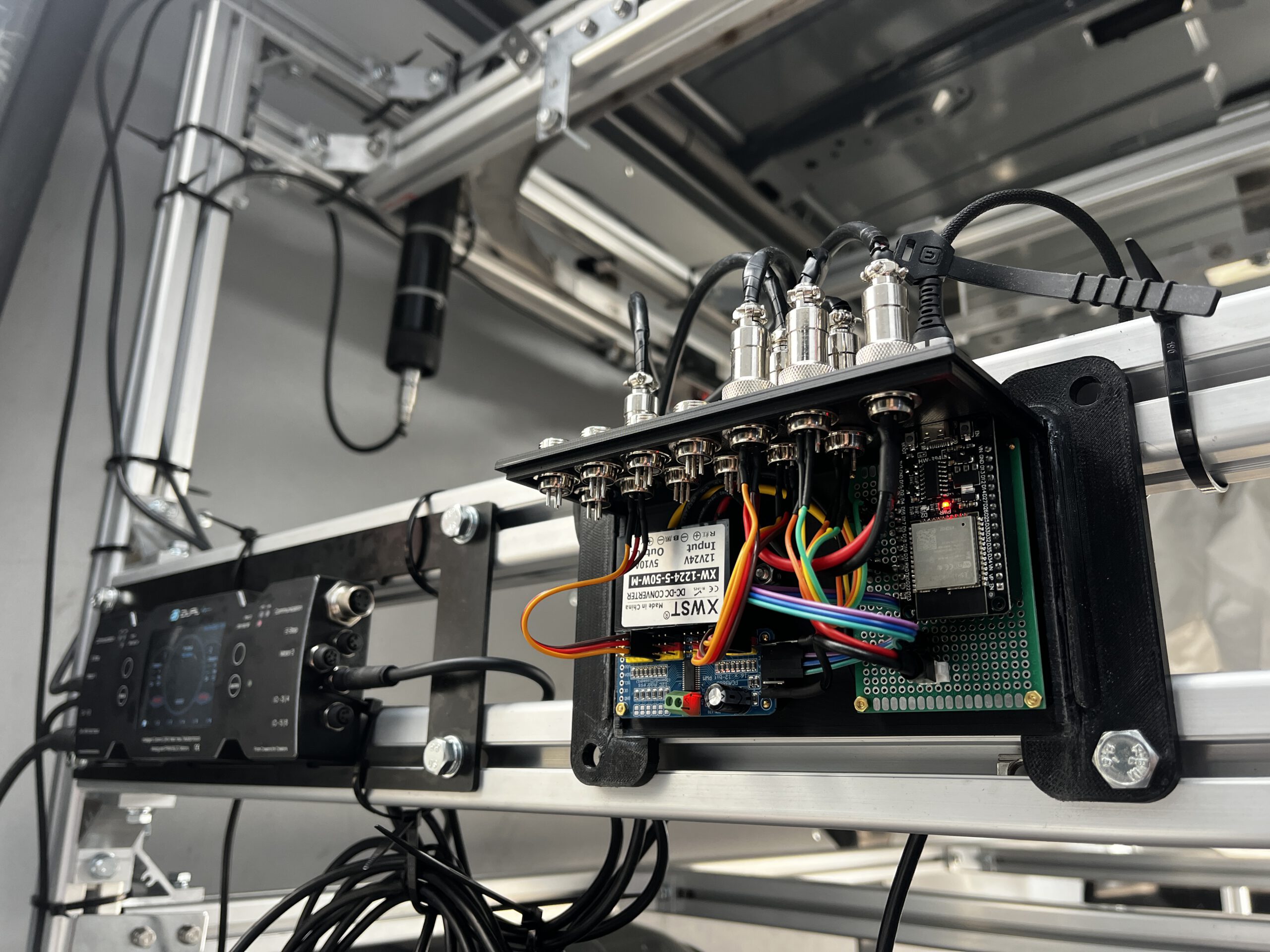

Sensors & Actuators

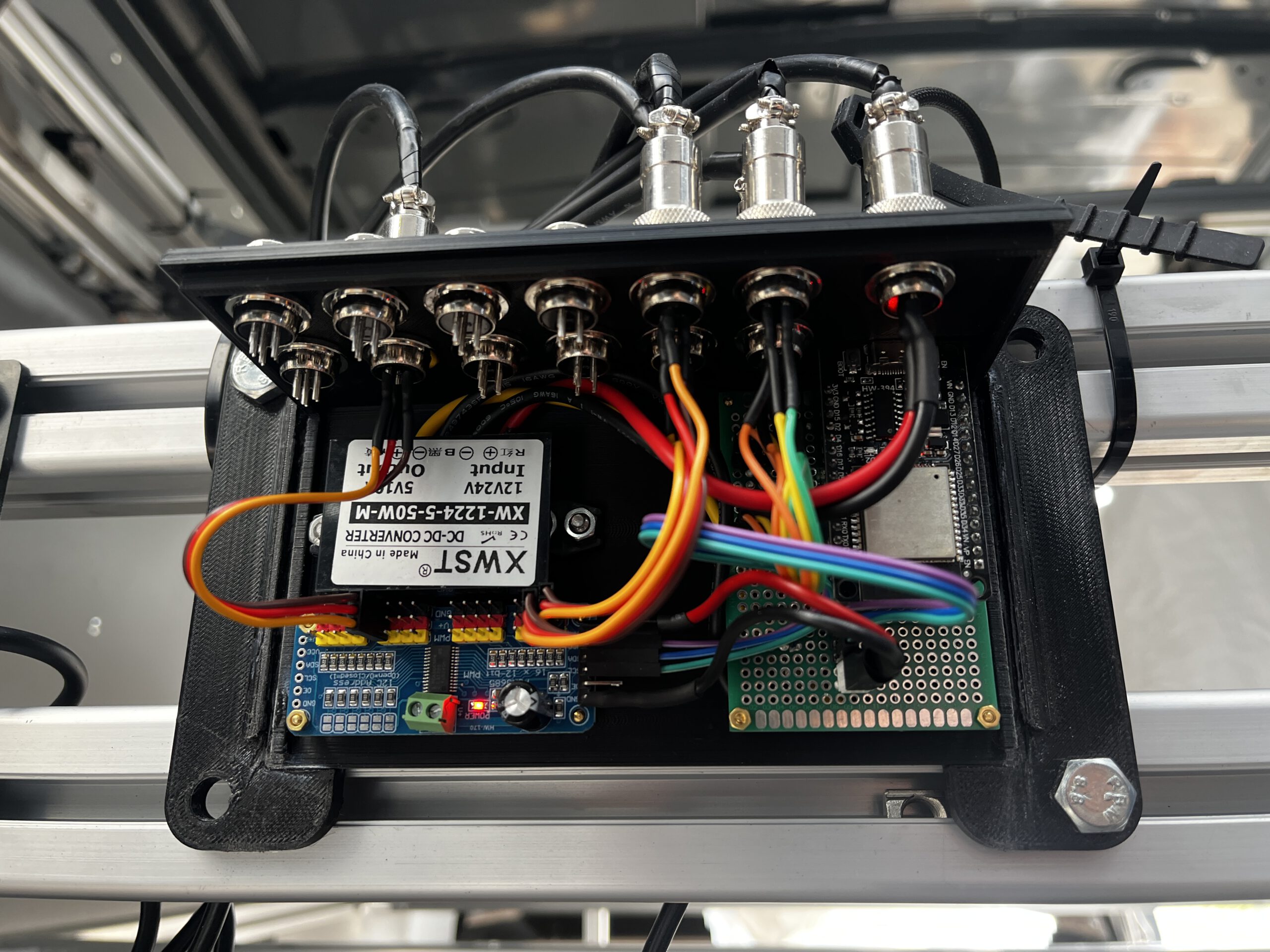

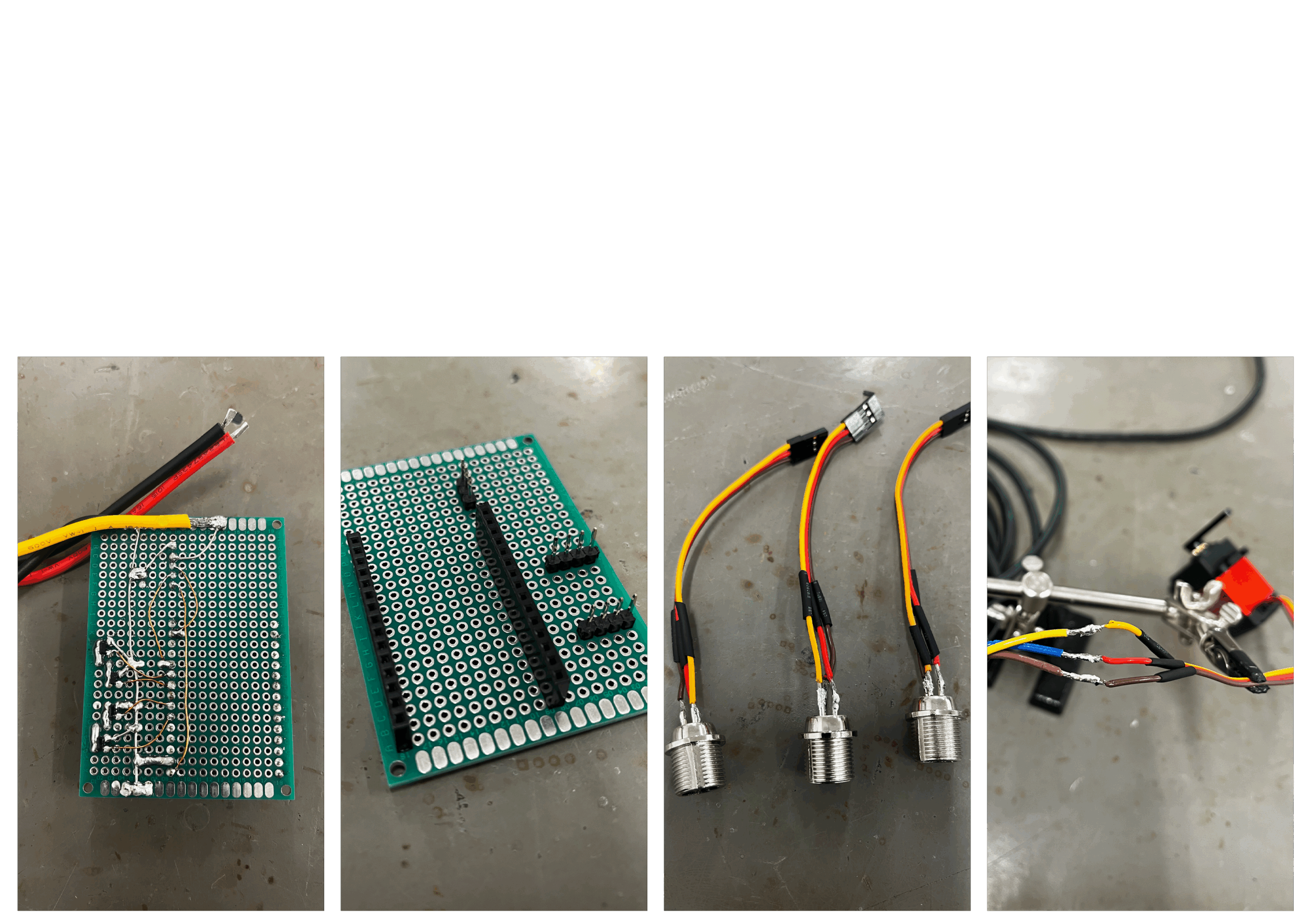

Since my Final Master Project is a larger-scale prototype in an industrial context, my goal for the project was to design more reliable and modular embedded systems. As a sensor, I used an RFID reader to scan pouches (Image 25). DC and servomotors were used as actuators to drive, switch, and buffer pouches (Images 26 and 27). These systems were divided into separate embedded ESPs that report over Serial to central C++ firmware on my laptop to make the system more robust (Images 28 to 30). Since the mechanical components were delayed, the realization process became fast-paced. This modular electronics approach respected and anticipated this as it facilitated more controlled troubleshooting and prototype scaling. Actuating the driven chain needed to be done from the outside, requiring many micro-decisions to secure and stabilize the chain (Images 21 to 23). Additionally, to enable buffering, the forces between the servomotors and the spring-loaded buffering arms needed to be carefully considered, requiring calculation and thorough testing (Image 27). I learned that my electrical interest and expertise are more with sensors than actuators, closely intertwining with my interest in self-tracking. In the future, I need to explore how this interest can be used productively within my role at the company.

technology & Realization | math, data & computing

Programming & Data

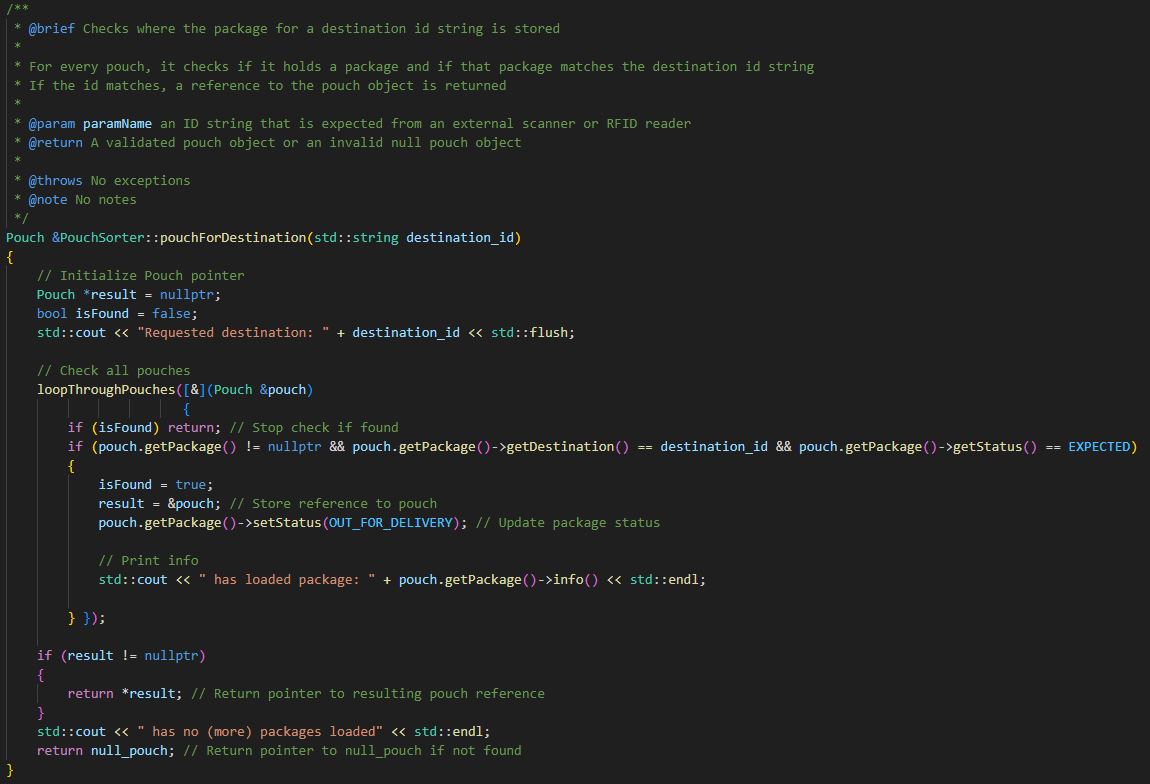

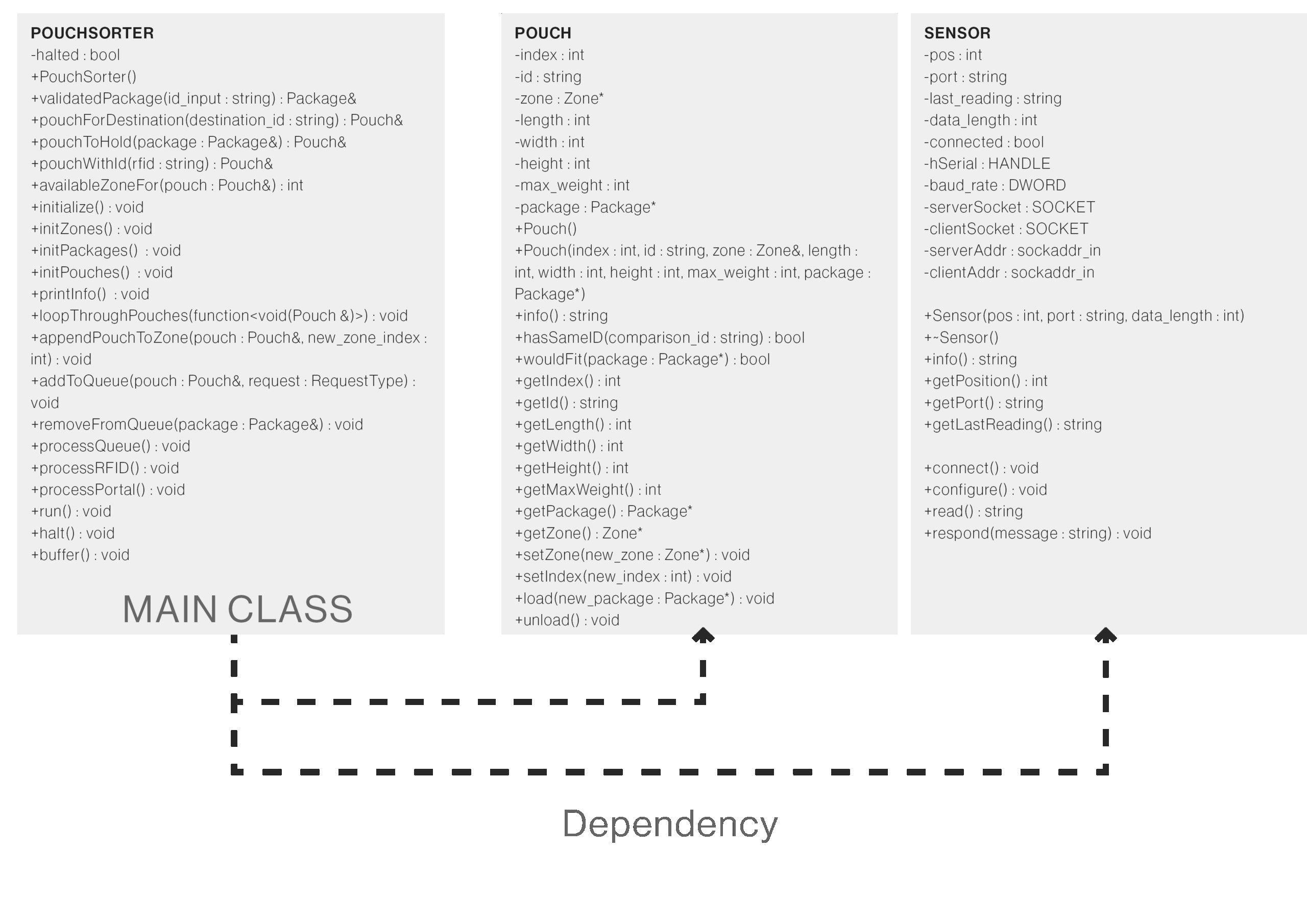

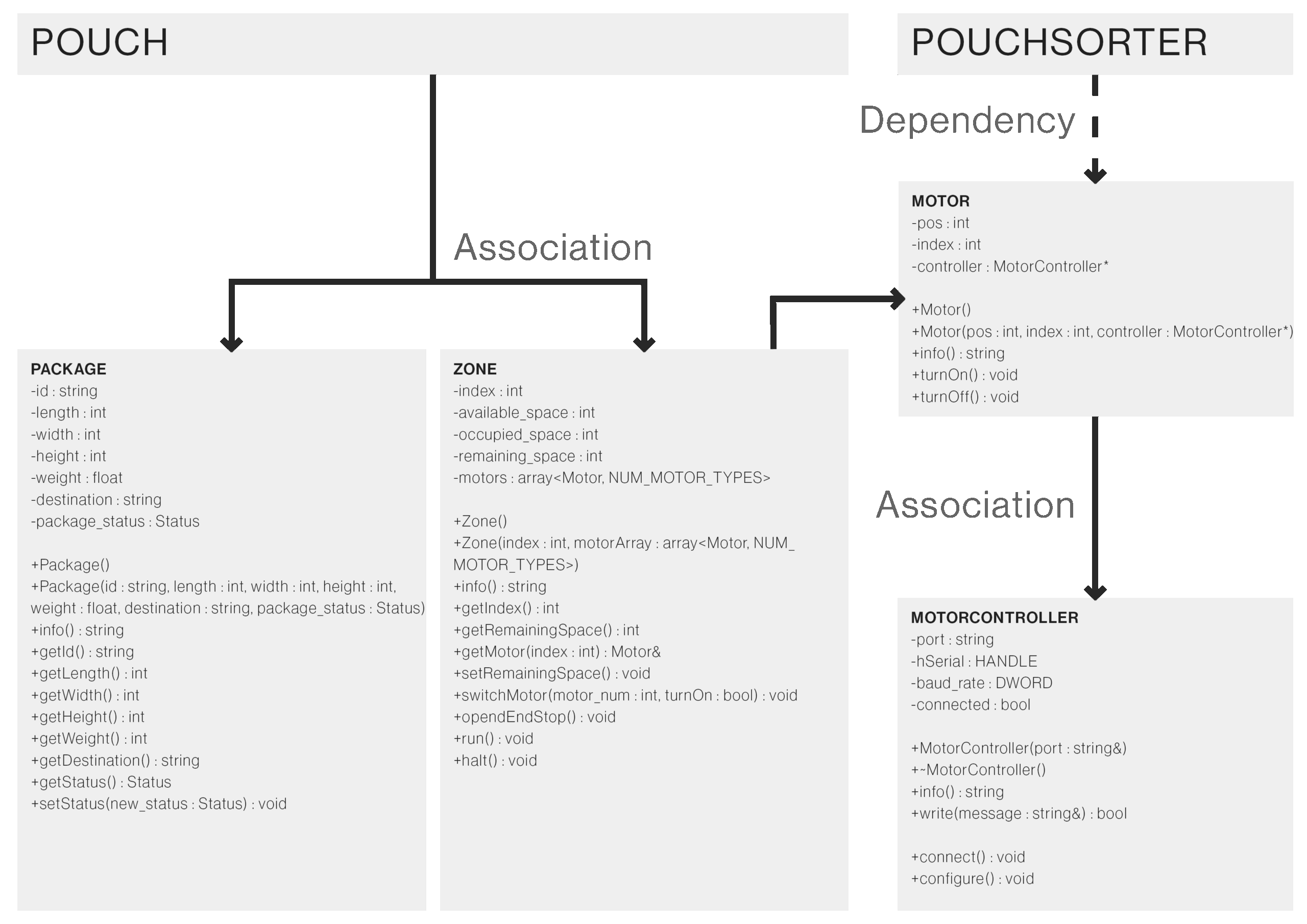

In my career, I want to combine designing with true hands-on realization, meaning that I need deeper expertise in at least one regard. As I experienced being involved in hard engineering at EPHI, high-fidelity mechanical and electrical engineering are not within my expertise or my interest. Conversely, my interest in programming grew fonder, as I see it as the ingredient to bring products to life, enabling high nuance and interaction. Therefore, my intended development is to gain professional affinity in programming (mainly C++) to enable involvement with software engineers to write production-ready firmware. In pursuit of this, my goals for the project were to develop robust between-systems communication and well-documented object-oriented firmware, enabling future development and collaboration. In the Final Master Project, I learned to use pure C++ and pointer-based logic and references (memory address instead of value) to properly pass Object arguments (Image 31). For data management, I relied on central CSV databases for the pouches and packages. For documentation, I learned about the Unified Modeling Language (UML) (Image 32). Throughout, my confidence and efficiency in writing structured code grew significantly. For my future development, I want to explore UML further to draft interaction flows before writing code, and am seeking online courses to follow.

technology & Realization | math, data & computing

creativity & aesthetics

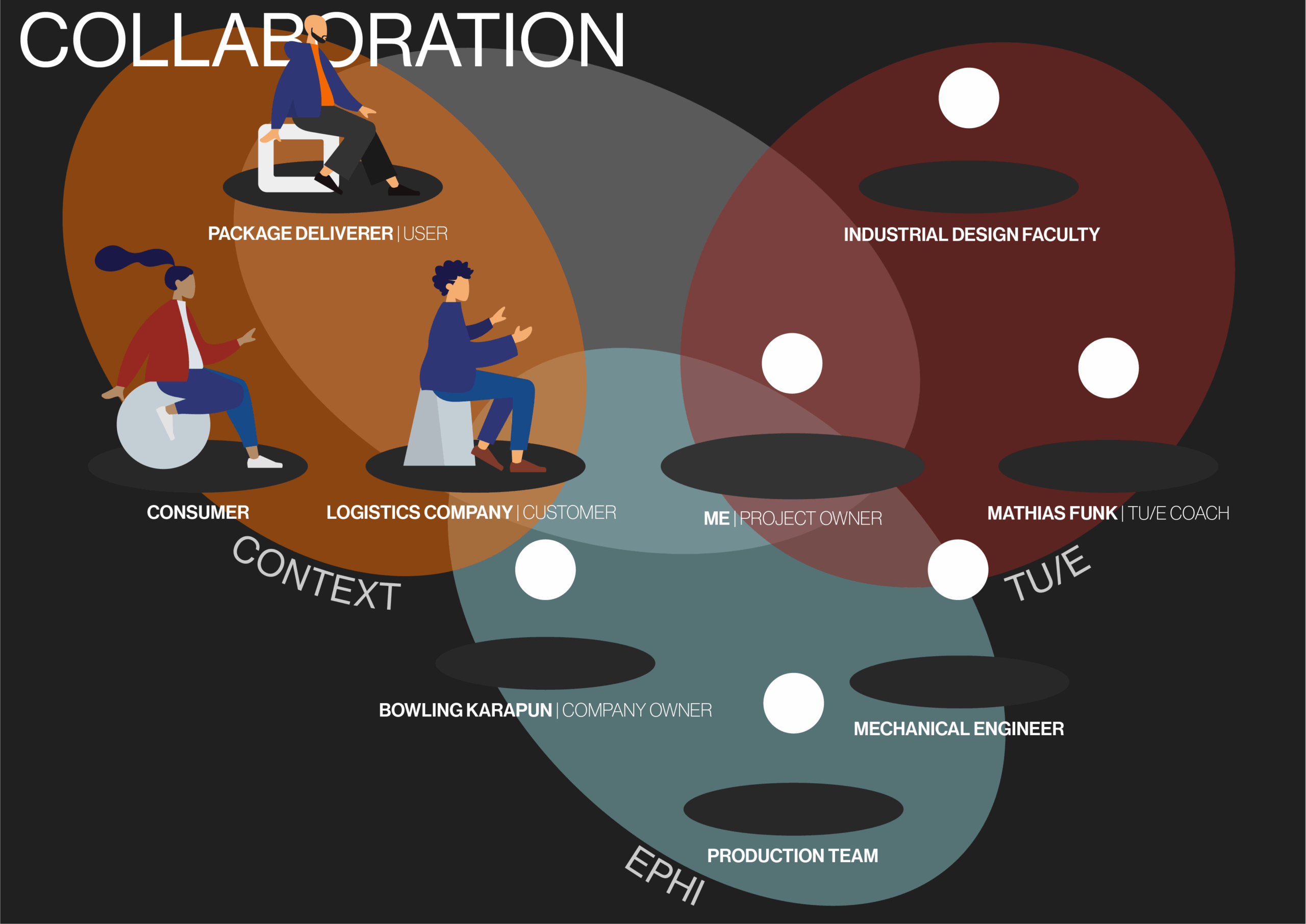

Project Management & Stakeholder Communication

In light of the complex multi-disciplinary nature of my Final Master Project and my future career as Project Manager, this theme became central to my intended development. My goals were to plan a design process with internal and external stakeholders involved, define a group vision, and realize a value proposition for this vision. Therefore, I defined personal success criteria, sought out expertise within the company, mapped the communication structures between the stakeholders (Image 33), and constructed a group vision with them. Additionally, I anticipated risks and developed a backup plan for the design process. This was proven valuable, as other responsibilities hindered engineer involvement, which now didn’t prevent me from realizing prototypes and value propositions for the external stakeholders. Nonetheless, I changed my approach for the future and the project that I manage currently. First, the process should rely on funded phases, not “wasting” resources and time. This means 3D modeling and rendering become integrated factors to sell (part of) a concept before development is initiated. Second, I lack authority and confidence in stakeholder communication, especially in contact with externals with more in-field experience. To improve this, I am leveraging the methods I used for contextualization to quickly fill knowledge gaps, improving my confidence.